Message is too long that i cannot comprehend whatever its saying

ENGINEERING

& INNOVATION

BEYOND

EXPECTATION

Engineered System & Specialties

905.696.9292

877.896.9292

Applications

Technologies

Customer Service

Life Sciences

Food & Beverage

Agitation & Mixing

Automation

Cleaning and Sterilization in Place

Components-Vessel Accesories

Vessels & Piping

Customer Service

Audit, Consultancy & Troubleshooting

maintenance & Spare Parts

Calibration & Qualification

Retrofits & Automation Upgrade

We Design

We Manufacture

Product Support

Life Sciences

Food & Beverage

Wine & Spirits

Key Facts

History

Our Core Values

Home

Industries

Pharmaceutical & Biotech

Food & Beverage

Application

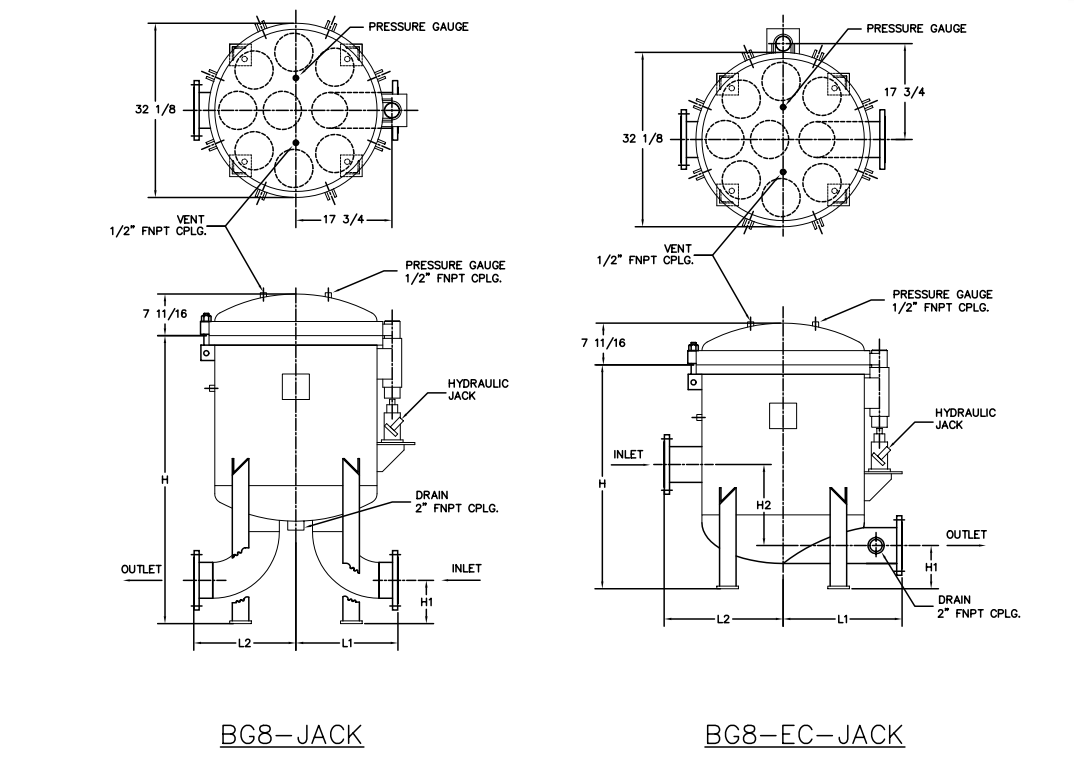

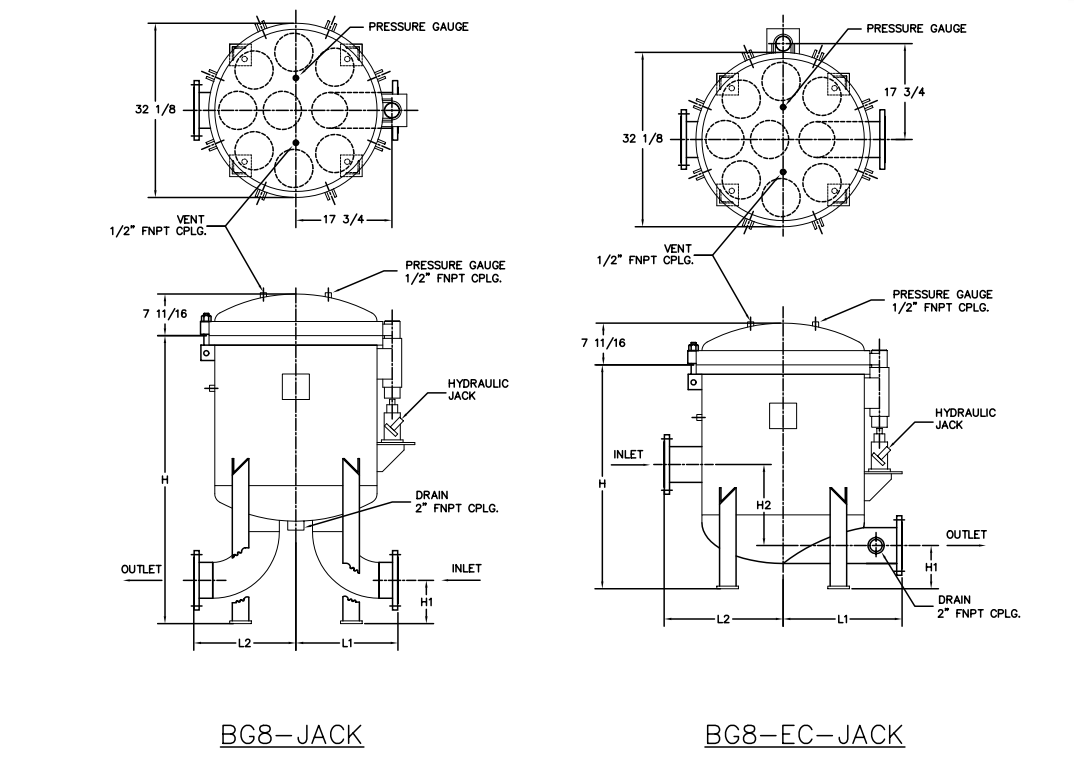

Filter Vessels

Bag Filter Vessels

Cartridge Filter Vessels

Charcoal Filter Vessels

Filter Media

Competencies

Filter Media

Filter Media

Filter Media

Quality Systems

Contact

Careers

LIFE

SCIENCE

A WORLD LEADER IN FERMENTERS & BIOREACTORS

Pierre Guerin offers you the knowledge of numerous applications gained from several decades experience, for the production of biological & sterile products

Model

PRIMO AUTOCLAVABLE BIOREACTORS & FERMENTERS INDUSTRIAL QUALITY - 1L TO 10L USEFUL

TECHNICAL SHEET

CONTACT

NEPTUNE™ command control system, applied to the entire STEPWELL INTERNATIONAL range of fermentation and cell culture equipment, facilitates the industrialization of your processes from the Research & Development stage to production, whether in a GLP or GMP environment. TECHNICAL CHARACTERISTICS - Benefits for the user -

- Ergonomic, modular and compact system

- Five standard interchangeable vessels, from 1 to 10 L w/v* for fermentation or cell culture, plus custom vessels on request

- Easy installation and maintenance

- NEPTUNETM Control system with user friendly and intuitive interface (12.1’’ Touch screen PANEL PC) suitable for Research & Development or small scale production in GLP / GMP environments

- Micro-PLC SIEMENS – SCADA based Control technology ensuring robustness and reliability to the system

- Software developed from non-proprietary platforms complying with GMP requirements (21 CFR PART 11 and GAMP 5)

- Remote supervision of multiple bioreactors via ETHERNETTM network

DESCRIPTION

Autoclavable bioreactors.

APPLICATIONS Microbial or cell culture on an R&D scale.

APPLICATIONS Microbial or cell culture on an R&D scale.

| Month | Savings | Credit |

|---|---|---|

| January | $100 | $100 |

| February | $80 | $80 |

| Sum | $180 |

NEPTUNE™ command control system, applied to the entire STEPWELL INTERNATIONAL range of fermentation and cell culture equipment, facilitates the industrialization of your processes from the Research & Development stage to production, whether in a GLP or GMP environment. TECHNICAL CHARACTERISTICS - Benefits for the user -

- Ergonomic, modular and compact system

- Five standard interchangeable vessels, from 1 to 10 L w/v* for fermentation or cell culture, plus custom vessels on request

- Easy installation and maintenance

- NEPTUNETM Control system with user friendly and intuitive interface (12.1’’ Touch screen PANEL PC) suitable for Research & Development or small scale production in GLP / GMP environments

- Micro-PLC SIEMENS – SCADA based Control technology ensuring robustness and reliability to the system

- Software developed from non-proprietary platforms complying with GMP requirements (21 CFR PART 11 and GAMP 5)

- Remote supervision of multiple bioreactors via ETHERNETTM network

New Title

Left Side Title

Our Quality Program includes, such as:

- List Item 1

- List Item 1

- List Item 1

- List Item 1

- List Item 1

- List Item 1List Item 1List Item 1List Item 1List Item 1List Item 1List Item 1

Right Side Title

- List Item 1

- List Item 1

- List Item 1

- List Item 1

- List Item 1

- List Item 1List Item 1List Item 1List Item 1List Item 1List Item 1List Item 1

- List Item 1

- List Item 1

- List Item 1

- List Item 1

LIFE SCIENCES

FOOD & BEVERAGE

BIOTECHNOLOGIES

Bioreactors & fermenters autoclavable primo

Control suite for bioprocess applications neptune™

Harvest and inactivation vessels biovessel™

Media and buffer preparation vessels biovessel™

Single-use bioreactors nucléo™

Steam in place cell culture bioreactors biocell™ lab & pilot series

Steam in place microbial fermenters biopro™ evo series™

Steam in place microbial fermenters biopro™ lab & pilot series

Turnkey fermentation and cell culture units

Unifertex a universal fermenter for growing micro-organisms

PHARMACEUTICS

Formulation vessels biovessel™

Storage and filling vessels biovessel™

Turnkey pharmaceutical units in gmp environment

PERSONAL CARE

Cream mixers mcd™

Melting vessels and process vesselsfor shampoos and lotions biovessel™

Storage and filling vessels biovessel™

Turnkey personal care units

HYDROTHERAPY

Thermal water storage vessels eth

Turnkey hydrotherapy units

LIFE

LIFE

SCIENCES

Albit

Russia

Baxter Belgium Italy

Swiss

Bilthoven Biologicals

Netherlands

Biovac South

Africa

BP Biofuel & Verenium

USA

Ceva Biomune Hungary

USA

CPI

UK

Danisco UK

France

DianaPlantSciences

USA

Elephant Vert

Morocco

Epitopix

USA

Excelvision

France

Fermentalg

France

Gilead

USA

GSK & GSK Vaccine UK Belgium France Singapore

USA

Hualan Bio

China

L'Occitane

France

Lily

France

Lonza UK

USA

Meddimune

USA

Merck Millipore France

Swiss

Merial France Italy

USA

NIBRT

Irlande

Novartis France

Singapore

Pfizer France

Irlande

Public Health England

UK

Samsung Biologics

Korea

Sanofi & Sanofi Pasteur Canada

France

Sisley

France

Takeda

USA

Tecon

China

Unither

France

Volac

France

Protgen

China

Minhai Biotechnology

China

CONTACT US

Upload Document Attachment

Hello

![]()

Wajax Industrial Components

Graystone & Associates

Eggelhof Inc.

Becker & Associates, Inc.

Visit Our Facility in Person!

| Monday | 8a.m.–4p.m. |

| Tuesday | 8a.m.–4p.m. |

| Wednesday | 8a.m.–4p.m. |

| Thursday | 8a.m.–4p.m. |

| Friday | 8a.m.–4p.m. |

12 Jobs Available

Scheduling / launching technician (M / F)

New York

Scheduling / launching technician (M / F)

New York

Scheduling / launching technician (M / F)

New York

Scheduling / launching technician (M / F)

New York

Scheduling / launching technician (M / F)

New York

Scheduling / launching technician (M / F)

New York

Scheduling / launching technician (M / F)

New York

Scheduling / launching technician (M / F)

New York

Scheduling / launching technician (M / F)

New York

updated 4 days ago

Scheduling / launching technician (M / F)

New York

New York

Publication date: 01/28/2021

Ref: PGF00111 / SI

What can we accomplish together?

Attached to the Design Office within Industrial Operations , your role is to carry out the manufacturing file, organize and anticipate the purchases defined by the BOs so that all the parts are ready for the start of manufacturing.

For this, you will be in charge, among other things, of:

- Receive and analyze the BOM and / or pre-approvals (List of components)

- Analyze customer manufacturing standards (ASME, DESP, ATEX, etc.) provided for in the plans and in conjunction with the Traceability and Methods teams

- Define the articles and create them in the MDD

- Update the BOM and pre-approvals by filling in the item codes for updating

- Create BOM items, fill in item codes, create Production Orders (OF)

- Receive the "Good for manufacture" plans and create the production range (list of operations and time allocated)

- Manage unforeseen events and propose substitute solutions

- Check the BOM and finalize the purchasing / procurement process

- Edit plans / nomenclature file and distribute to production teams to start the manufacturing phase

- Carry out its missions in compliance with the Quality and Safety rules

- Holder of a Bac + 2 ROC / CRCI or mechanical training

- You have a first successful experience in a similar function.

- You with technical knowledge of boiler making and / or piping, particularly in the manufacturing and assembly processes.

- You master the Pack office / Autocad / Inventor / ERP tools.

- Autonomous and rigorous, you also have good interpersonal skills.

- You know how to organize and prioritize your files.

Apply for the offer

Application - "Intervention technician Agence Lyon (M/F) asparagus"

Application - "Intervention technician Agence Lyon (M/F) asparagus"

or

Application - "Intervention technician Agence Lyon (M/F) asparagus"

Application - "Intervention technician Agence Lyon (M/F) asparagus"

1

CV

2

FORM

Upload your Resume

or

Name Prefix

Firstname

Lastname

Email Address

Phone Number

Highest Education Attained

Position you are Applying for

Salary Expectation

Upload Your Cover Letter

Select File